A lap joint flange is a two-piece flange assembly commonly used in piping systems where frequent dismantling, alignment flexibility, and cost efficiency are required. It consists of a stub end (also called a lap joint stub) and a backing flange. The backing flange rotates freely around the stub end, making alignment with bolt holes easy during installation.

Lap joint flanges are widely used in industries where pipelines need regular inspection, cleaning, or modification.

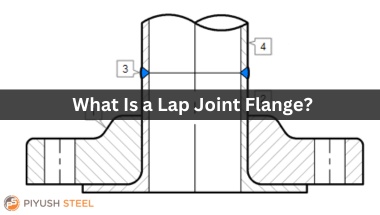

Components of a Lap Joint Flange

A lap joint flange system has two main parts:

1. Stub End

-

Welded directly to the pipe

-

The pipe end is flared or “lapped”

-

Comes in short pattern and long pattern designs

2. Backing Flange

-

Slides over the stub end

-

Not in direct contact with the process fluid

-

Can be made from lower-cost material

This design allows the backing flange to rotate freely, simplifying installation and maintenance.

How a Lap Joint Flange Works

The stub end is welded to the pipe, and its flared end forms the sealing surface. The backing flange supports the bolting and applies pressure to seal the joint. Since the flange itself does not touch the fluid, it does not require corrosion-resistant material—only the stub end does.

Types of Lap Joint Flanges

1. Standard Lap Joint Flange

-

Used with standard stub ends

-

Common in low to medium pressure piping

2. Long Pattern Lap Joint Flange

-

Uses long-pattern stub ends

-

Suitable where thicker piping or special alignment is required

3. Short Pattern Lap Joint Flange

-

Uses short-pattern stub ends

-

More economical and widely used in industrial piping

Materials Used in Lap Joint Flanges

Stub End Materials

-

Stainless Steel (304, 316, 321, 904L)

-

Duplex & Super Duplex Steel

-

Nickel Alloys (Inconel, Monel, Hastelloy)

Backing Flange Materials

-

Carbon Steel

-

Stainless Steel

-

Alloy Steel

This combination helps reduce overall system cost while maintaining corrosion resistance where needed.

Pressure Ratings & Standards

Lap joint flanges are manufactured as per international standards such as:

-

ASME / ANSI B16.5

-

ASME B16.47

-

DIN, BS, and EN standards

Available pressure classes typically include:

-

Class 150

-

Class 300

-

Class 600

Lap joint flanges are generally not preferred for very high-pressure applications.

Advantages of Lap Joint Flanges

✔ Easy pipe alignment due to rotating flange

✔ Ideal for systems requiring frequent dismantling

✔ Lower cost when used with expensive alloy pipes

✔ Reduced need for precision bolt hole alignment

✔ Backing flange does not contact fluid

Limitations of Lap Joint Flanges

✘ Not suitable for high-pressure or high-temperature systems

✘ Lower strength compared to weld neck flanges

✘ Requires additional component (stub end), increasing part count

Applications of Lap Joint Flanges

Lap joint flanges are commonly used in:

-

Chemical processing plants

-

Oil & gas piping (low pressure lines)

-

Food & beverage industries

-

Pharmaceutical piping systems

-

Water treatment plants

-

Corrosive fluid handling systems

They are especially useful where pipelines need frequent cleaning or replacement.

Lap Joint Flange vs Weld Neck Flange

| Feature | Lap Joint Flange | Weld Neck Flange |

|---|---|---|

| Alignment | Very easy | Moderate |

| Cost | Lower (with alloy pipes) | Higher |

| Strength | Moderate | High |

| Pressure Handling | Low–Medium | High |

| Maintenance | Easy | Difficult |

Why Choose Lap Joint Flanges?

Lap joint flanges are the preferred choice when:

-

Pipe alignment is critical

-

Frequent dismantling is required

-

Cost reduction is a priority

-

Corrosion-resistant piping materials are used

Conclusion

A lap joint flange is a practical and cost-effective solution for piping systems that require flexibility, easy maintenance, and corrosion resistance without excessive cost. While they are not designed for extreme pressure conditions, their ease of installation and economical benefits make them a popular choice across many industries.