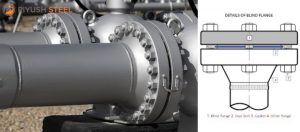

Blind flanges are essential components in piping systems, widely used across industries for sealing off pipe ends and ensuring system safety. These versatile flanges offer a reliable solution for temporary or permanent closures, making them ideal for both maintenance and system expansion. At Piyush Steel, we provide high-quality blind flanges along with a wide range of other flanges and pipe fittings to meet diverse industrial needs.

Blind Flange Uses

Blind flanges are indispensable in various applications due to their functionality, durability, and compatibility with different piping systems. Below are the top 10 uses of blind flanges:

1. Sealing Pipe Ends

Blind flanges are primarily used to close the ends of pipelines, preventing the escape of liquids, gases, or other substances. This ensures system integrity by providing a leak-proof and secure closure. Industries like oil and gas rely on blind flanges to safely seal pipelines carrying hazardous materials. Their design allows for easy installation and removal, making them suitable for both permanent and temporary closures. High-strength materials such as stainless steel and alloy steel ensure durability and reliability in demanding environments.

2. Pressure Testing

In pipeline systems, blind flanges play a key role during hydrostatic or pneumatic pressure testing. By sealing off sections of the pipeline, engineers can safely check for leaks, weak points, or structural issues under controlled pressure. This ensures that the system is safe and ready for operation. Blind flanges are particularly useful for temporary isolation during testing phases. Materials like carbon steel or duplex steel are commonly used for these applications, providing the strength needed to handle high-pressure conditions.

3. Maintenance and Inspection

Blind flanges allow specific sections of a pipeline to be isolated during maintenance or inspection. This ensures that the rest of the system remains operational while work is being carried out. For example, in refineries or chemical plants, blind flanges are used to safely isolate hazardous areas during maintenance. They provide easy access to critical sections without disrupting the entire system. Corrosion-resistant materials like duplex or super duplex steel enhance their longevity, even in harsh industrial environments.

4. System Expansion

Blind flanges are often used as temporary closures for pipelines that are designed for future expansion. They seal pipe ends until new sections are required, allowing for seamless integration when expansion is needed. This flexibility is especially useful in construction projects and industrial setups where system modifications are common. Blind flanges can be removed easily without causing damage to the pipeline, ensuring cost-effective scalability. Their availability in various sizes and materials ensures compatibility with diverse systems.

5. Flow Redirection

In complex piping systems, blind flanges are used to redirect the flow of liquids or gases by sealing off unused or redundant pipe openings. This helps optimize the system’s flow pattern based on operational requirements. For example, in chemical manufacturing plants, blind flanges can help manage flow routes to improve production efficiency. They also prevent leaks or pressure drops in redundant pipelines. The versatility of blind flanges makes them a valuable asset in dynamic industrial processes.

6. Industrial Shutdowns

Blind flanges are crucial during industrial shutdowns for isolating sections of piping systems safely. By sealing off specific areas, they prevent leaks or contamination while maintenance or replacement work is performed. This is particularly important in high-pressure systems, such as power plants or chemical refineries, where safety is a top concern. Blind flanges designed for extreme conditions, such as those made from Inconel or super duplex steel, ensure optimal performance during critical shutdown operations.

7. Offshore and Subsea Applications

Blind flanges are widely used in offshore and subsea pipelines, where they withstand high-pressure and corrosive environments. In underwater pipelines, they seal unused pipe ends and prevent seawater ingress, ensuring the system’s reliability. Materials like super duplex steel and nickel-based alloys, such as Inconel, are commonly used for their exceptional resistance to saltwater corrosion. In oil rigs and marine environments, blind flanges provide a safe and durable solution for sealing pipelines in challenging conditions.

8. High-Temperature Systems

In high-temperature environments, such as power plants and chemical processing units, blind flanges made from heat-resistant materials like alloy steel and Inconel are indispensable. These flanges maintain their structural integrity even under extreme thermal stress. They are commonly used in boiler systems, steam pipelines, and reactors, where temperatures can exceed several hundred degrees Celsius. Their design ensures safety and performance in conditions that would compromise standard materials.

9. Water Treatment Plants

Blind flanges are extensively used in water treatment plants for isolating sections of the pipeline during maintenance, cleaning, or upgrades. They provide an effective seal, allowing operators to carry out work without disrupting other parts of the system. Corrosion-resistant materials, such as stainless steel, are preferred for handling exposure to water, chemicals, and varying temperatures. Blind flanges also ensure a tight seal in pressurized systems, improving the plant’s overall operational efficiency.

10. Storage Tanks and Pressure Vessels

Blind flanges are used to seal openings in storage tanks and pressure vessels, providing a secure environment for storing liquids or gases. This is particularly important in industries such as petrochemicals, natural gas, and pharmaceuticals, where preventing leaks is critical. These flanges allow for easy access during inspections and maintenance while ensuring the safety of the stored materials. Durable materials like alloy steel or duplex steel are often chosen for their ability to handle high pressures and corrosive conditions.

Blind flanges play a vital role in industrial piping systems, offering unmatched reliability and versatility. Whether sealing pipelines, enabling system expansion, or managing high-pressure environments, they ensure operational efficiency and safety. With a wide range of materials and specifications available, blind flanges are tailored to meet the unique demands of various industries, ensuring long-term performance and durability.

Why Choose Piyush Steel for Blind Flanges and Other Flanges?

At Piyush Steel, we pride ourselves on offering high-quality blind flanges manufactured to meet international standards like ASTM, ASME, DIN, and EN. Our blind flanges are available in various materials, including Stainless Steel (SS304, SS316), Duplex Steel, Super Duplex Steel, Alloy Steel, and Inconel, ensuring compatibility with any industrial requirement.

In addition to blind flanges, we provide a comprehensive range of pipe fittings and flanges, such as:

- Weld Neck Flanges

- Slip-On Flanges

- Socket Weld Flanges

- Threaded Flanges

- Lap Joint Flanges

- Reducing Flanges

Our extensive inventory also includes elbows, tees, reducers, couplings, and other fittings, making us your one-stop solution for all piping system components. With our commitment to quality, on-time delivery, and competitive pricing, Piyush Steel has become a trusted name in the industry.

For inquiries or more information, mail us at – [email protected]. Let us help you find the right flanges and fittings for your projects!