When it comes to pipe fittings, choosing the right component is crucial to ensure the efficiency and safety of your systems. Among the many types of plugs available, bull plugs and hex plugs are two commonly used fittings. Although they serve similar functions in sealing pipes, they differ in their design, application, and advantages. In this blog, we’ll break down the differences between bull plugs and hex plugs and discuss their uses in various industries.

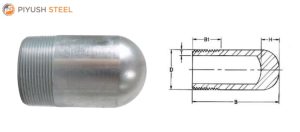

What is a Bull Plug?

A bull plug is a type of pipe plug used to seal the end of a pipe. It has a rounded or dome-like shape that fits tightly inside the pipe, creating a secure and reliable seal. Bull plugs are typically used in high-pressure systems as they are designed to distribute pressure evenly. They are often used in plumbing, gas, and oil industries where a long-lasting seal is required. Bull plugs are easy to install and are often used in applications where frequent maintenance or removal is not necessary.

What is a Hex Plug?

A hex plug is a type of pipe plug with a hexagonal shape, which makes it easy to install or remove using a wrench or tool. It has a flat end that seals the pipe opening securely. Hex plugs are commonly used in threaded pipe systems and are ideal for applications requiring periodic maintenance or access. The hexagonal shape ensures better grip and ease of tightening or loosening. They are widely used in industries like automotive, oil and gas, and machinery where regular adjustments are needed.

Bull Plug vs Hex Plug |

||

|---|---|---|

| Attribute | Bull Plug | Hex Plug |

| Design | The bull plug has a rounded, smooth shape that fits tightly into pipe ends to seal them off. The shape is like a dome or cap. | The hex plug has a flat end with a hexagonal shape, making it easy to tighten or remove with a wrench or similar tool. |

| Installation | Installed easily by hand or with basic tools. No special equipment needed, so it is simple to apply and remove in many cases. | Requires a wrench or tool for installation and removal. The hexagonal shape helps make it easier to tighten or loosen in pipe systems. |

| Pressure Handling | The rounded shape is designed to handle higher pressure better. It helps spread the pressure evenly across the plug. | Can handle moderate to high-pressure systems but may not be as effective at distributing pressure evenly as a bull plug. |

| Sealing Function | Seals pipe ends securely, preventing any leaks. The design ensures a tight, reliable seal for a variety of applications. | Used to seal threaded pipe openings. The hex plug is often used when you need a quick removal or access to a pipe opening. |

| Use Cases | Often used in plumbing, gas, and oil systems. Ideal for applications where you need a permanent seal or temporary sealing during maintenance. | Common in industries like oil, gas, automotive, and machinery. Used for blocking or sealing threaded pipe openings where access is needed regularly. |

| Maintenance | Typically not removed often, making it ideal for situations where a permanent seal is needed or where maintenance is infrequent. | Easy to remove and replace. Ideal for systems that need regular access, adjustments, or maintenance. |

| Applications | Used for closing off pipe ends, preventing dirt or debris from entering the pipes, and ensuring a reliable seal in high-pressure environments. | Used for sealing threaded holes or pipe openings in various industries. Great for sealing ports where frequent maintenance is needed. |

| Materials | Typically made from materials like stainless steel, carbon steel, or other durable alloys that resist corrosion and can withstand pressure. | Made from metals such as stainless steel, carbon steel, or alloys, ensuring durability and resistance to corrosion, especially in tough environments. |

| Strength & Durability | Excellent for long-lasting sealing, especially in high-pressure systems. Its design ensures a durable seal without frequent maintenance. | Reliable and strong, but designed for ease of installation and removal. More suited for applications with moderate pressure or regular changes. |

| Cost | Generally more affordable for permanent applications. Since it’s used less frequently, it can be cost-effective for many long-term installations. | Usually slightly more expensive due to the ease of installation and removal. A good investment for industries needing regular access to the system. |

| Ease of Removal | Once installed, the bull plug is not often removed. Ideal for sealing where no further adjustments are needed. | Can be removed and replaced quickly using a wrench. Ideal when pipes need regular inspection or maintenance. |

| Sealing Effectiveness | Highly effective in creating a tight seal that prevents leakage. Its rounded design makes it perfect for sealing high-pressure systems. | Effective in blocking openings, but its flat design may not be as efficient as the rounded bull plug in handling extreme pressure. |

| Common Industries | Used in plumbing, oil, gas, chemical, and construction industries. Also used in machinery to seal pipe ends. | Common in industries like oil and gas, automotive, machinery, and other areas where easy access and sealing of threaded pipe openings are required. |

| Temperature Resistance | Can be used in high-temperature environments due to its durable material and strong seal. | Can withstand moderate to high temperatures depending on the material used but may require careful handling in extreme conditions. |

Conclusion

Both bull plugs and hex plugs serve the vital role of sealing pipe openings in various applications. Choosing between the two depends on factors like the type of system, the need for pressure handling, and how often you might need to remove or replace the plug. Piyush Steel offers a wide range of bull plugs and hex plugs tailored to your specific needs, ensuring reliability and quality across industries. Reach out to us for more information on our pipe fittings and sealing solutions.