A spectacle blind is a safety device used in piping systems to completely isolate or allow flow within a pipeline. It consists of two metal discs—one solid and one with a bore—connected by a small metal web. Because its shape resembles a pair of spectacles, it is commonly known as a spectacle blind.

Spectacle blinds are widely used in process industries where positive isolation is required during maintenance, inspection, or shutdown operations.

What Is a Spectacle Blind?

A spectacle blind is installed between two flanges in a piping system. By rotating or changing its position, operators can either:

-

Block flow completely (solid plate position), or

-

Allow flow (open ring or spacer position)

This provides visible and physical confirmation of pipeline isolation, making it safer than relying only on valves.

Components of a Spectacle Blind Flange

A spectacle blind flange assembly includes:

1. Blind (Solid Disc)

-

Completely blocks the flow

-

Used during maintenance or shutdown

2. Spacer (Open Ring)

-

Allows normal fluid flow

-

Matches the pipe bore diameter

3. Web or Handle

-

Connects the blind and spacer

-

Helps identify whether the line is open or closed

How a Spectacle Blind Works

The spectacle blind flange is sandwiched between two pipe flanges. When the blind side is aligned with the pipeline, flow is fully stopped. When the spacer side is aligned, the fluid flows freely through the system.

Switching positions typically requires:

-

Depressurizing the line

-

Removing flange bolts

-

Rotating or replacing the spectacle blind

Types of Spectacle Blinds

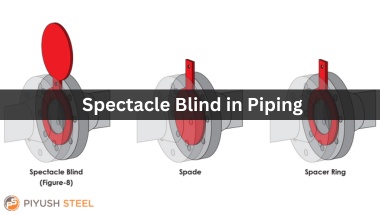

1. Figure-8 Spectacle Blind

-

Most common type

-

Two discs connected in a figure-8 shape

-

Used in horizontal and vertical piping

2. Paddle Blind

-

Single solid plate with a handle

-

Used where permanent isolation is required

3. Paddle Spacer

-

Single open ring plate

-

Used to restore flow after maintenance

(Paddle blind and paddle spacer are often used as alternatives to spectacle blinds.)

Materials Used in Spectacle Blinds

Spectacle blinds are manufactured in a wide range of materials depending on service conditions:

-

Carbon Steel

-

Stainless Steel (304, 316, 321, 904L)

-

Alloy Steel

-

Duplex & Super Duplex Steel

-

Nickel Alloys (Inconel, Monel, Hastelloy)

Material selection depends on pressure, temperature, and corrosion resistance requirements.

Standards & Thickness

Spectacle blinds are commonly manufactured according to:

-

ASME B16.48

-

ASME B16.5 (for matching flange dimensions)

-

DIN, BS, and EN standards

Thickness is calculated based on:

-

Pipe size

-

Pressure class

-

Design temperature

Pressure Classes & Sizes

Spectacle blinds are available in:

-

Pressure Classes: 150, 300, 600, 900, 1500

-

Sizes: From small bore piping to large diameter pipelines

They are designed to withstand full line pressure when the blind is in the closed position.

Advantages of Spectacle Blinds

✔ Provides positive and visible isolation

✔ Enhances safety during maintenance

✔ Simple design with high reliability

✔ Easy identification of line status (open or closed)

✔ No moving parts, low maintenance

Limitations of Spectacle Blinds

✘ Line must be depressurized before operation

✘ Not suitable for frequent switching

✘ Requires manual intervention and downtime

Applications of Spectacle Blinds

Spectacle blinds are widely used in:

-

Oil & gas pipelines

-

Refineries and petrochemical plants

-

Chemical processing industries

-

Power plants

-

Water and wastewater systems

-

Steam and high-temperature services

They are especially important in systems handling hazardous or high-pressure fluids.

Spectacle Blind vs Valve Isolation

| Feature | Spectacle Blind | Valve |

|---|---|---|

| Isolation | 100% positive | May leak |

| Visual Confirmation | Yes | No |

| Maintenance Safety | High | Moderate |

| Operation | Manual | Manual/Automatic |

Why Use a Spectacle Blind in Piping?

Spectacle blinds are used when:

-

Absolute isolation is required

-

Safety regulations demand physical separation

-

Valves alone are not considered reliable

-

Maintenance work is frequent and critical

Conclusion

A spectacle blind in piping is a critical safety component that ensures complete isolation of process lines during maintenance or shutdowns. Its simple yet effective design provides visible confirmation, making it a preferred choice in high-risk industrial environments.