Orifice flanges are specialized pipe flanges designed to work with orifice meters for measuring the flow rate of liquids and gases in pipelines. Unlike standard flanges, orifice flanges are machined with pairs of pressure tappings, eliminating the need for separate pressure taps on the pipe wall. These flanges are engineered to securely hold orifice plates and provide accurate flow measurements in industrial piping systems.

At Piyush Steel, we manufacture and supply premium quality orifice flanges in various materials, pressure classes, standards, and connection types to meet the demands of modern industrial applications.

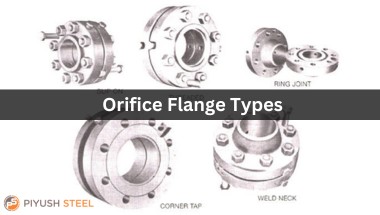

Classification of Orifice Flanges

Orifice flanges can be categorized based on several criteria — including connection type, orifice location, pressure class, and flange face type. Below we explore each type in detail:

Based on Connection Type

Different connection methods suit different installation requirements and operating conditions:

a) Weld Neck Orifice Flanges

-

Description: These feature a long tapered hub welded directly to the pipeline.

-

Uses: Ideal for high‑pressure and high‑temperature applications like petrochemical, oil & gas, and energy plants.

-

Advantage: Provides excellent structural integrity and reduced stress concentration.

b) Threaded Orifice Flanges

-

Description: These have internal threads for screwing onto threaded pipes.

-

Uses: Best for low to medium pressure systems where welding is difficult or impractical.

-

Advantage: Easy to install and remove without welding.

c) Slip‑On Orifice Flanges

-

Description: These flanges slip over the pipe and are then welded both inside and outside.

-

Uses: Suitable for lower pressure environments and general industrial piping.

-

Advantage: Simple alignment and welding make them cost‑effective for many applications.

d) RTJ (Ring Type Joint) Orifice Flanges

-

Description: These flanges use a precisely machined metal ring gasket to form a high‑integrity seal.

-

Uses: Common in high‑pressure, high‑temperature applications where leak prevention is critical.

-

Advantage: Offers superior sealing compared to raised face (RF) designs.

e) Blind Orifice Flanges

-

Description: Solid flanges that block off flow while retaining pressure tappings.

-

Uses: Used in systems where flow measurement needs to be temporarily isolated.

Based on Orifice Location (Bore Type)

The design of the orifice plate inside the flange helps match measurement needs:

a) Concentric Orifice Flanges

-

Feature: The orifice hole is centered in the flange.

-

Use Case: Accurate measurement of clean fluid flows such as water, steam, or gas.

-

Advantage: Provides uniform pressure drop and stable flow readings.

b) Eccentric Orifice Flanges

-

Feature: The orifice bore is offset from the pipe center.

-

Use Case: Ideal for fluids containing solids, slurries, or entrained gases.

-

Advantage: Reduces trailing eddies and blockages.

c) Square‑Edged Orifice Flanges

-

Feature: Precision square bore at the orifice.

-

Use Case: Applications that require high measurement accuracy and repeatability — such as custody transfer metering.

-

Advantage: Minimizes turbulence and provides a defined pressure drop.

Based on Pressure Classes

Orifice flanges come in standard ANSI/ASME pressure ratings such as:

-

Class 150, 300, 600, 900, 1500 and 2500

-

Suitable for various operational pressures from low to ultra‑high in pipeline systems.

These classes determine the flange’s temperature and pressure resistance, crucial for engineering design and safety.

Based on Flange Facing Types

a) Raised Face (RF)

-

The most common flange face.

-

Ease of installation and wide compatibility.

b) Flat Face (FF)

-

Used where mating flange has a flat face to minimize distortion.

c) Ring Type Joint (RTJ)

-

Best for leak‑proof services under high pressure.

(Piyush Steel stocks all common facing types as per industry standards.)

Materials & Standards for Orifice Flanges

At Piyush Steel, our orifice flanges are available in a wide range of materials and international standards such as ANSI/ASME B16.5, B16.36, DIN, BS, and more.

Materials Offered

✔ Carbon Steel (ASTM A105, A350)

✔ Stainless Steel (ASTM A182 304/316/904L)

✔ Alloy Steel (F5, F11, F22)

✔ Nickel & Duplex Alloys — Monel, Inconel, Super Duplex

✔ Custom materials as per project requirements

This range ensures suitability across industries such as oil & gas, chemical, power, pharmaceuticals, water treatment, and food processing.

Applications of Orifice Flanges

Orifice flanges are critical components in:

✅ Flow metering systems in oil & gas pipelines

✅ Chemical processing plants

✅ Power generation facilities

✅ Water & wastewater treatment

✅ Steam & compressed air monitoring

✅ Petrochemicals and more

Their robust construction, accurate pressure tappings, and compatibility with orifice plates make them ideal for precise flow measurement in demanding industrial environments.

Why Choose Piyush Steel Orifice Flanges?

At Piyush Steel, we provide:

🔹 High quality orifice flanges manufactured under strict quality control

🔹 Compliance with international standards (ANSI, ASME, DIN, BS)

🔹 Wide range of sizes, materials, and pressure classes

🔹 Customized solutions for specific industry needs

🔹 On‑time delivery and global export support

Conclusion

Understanding the types of orifice flanges is essential for choosing the right component for your flow measurement and process system. Whether it’s high‑pressure applications requiring RTJ flanges, or precision metering needing square‑edged or concentric orifice designs, Piyush Steel offers a comprehensive portfolio to meet your project demands.